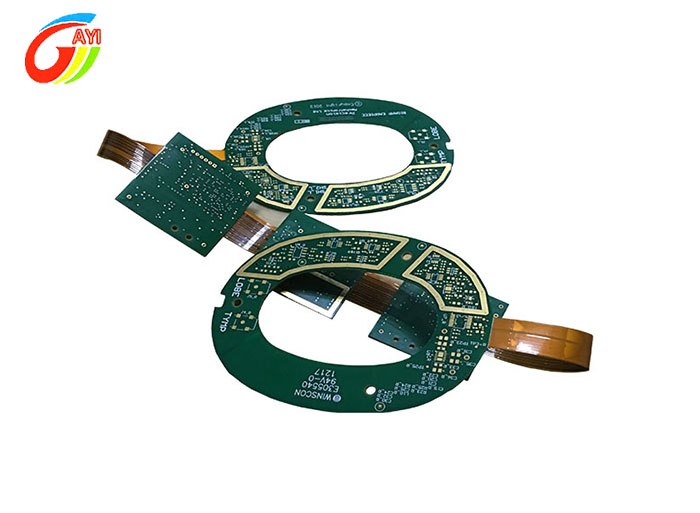

Soft and hard bonding board (Rigid_flex_PCB)is a combination of FPC and PCB. The production of soft and hard bonding board(Rigid_flex_PCB) should have both FPC production equipment and PCB production equipment.

First of all, the line and shape of the soft bonding board(Rigid_flex_PCB) are drawn by the electronic engineer according to the demand. Then, it is sent to the factory where the soft and hard bonding board can be produced. After the CAM engineer processes and plans the relevant documents, the FPC and PCB production lines required by the FPC production line are arranged to produce PCB.After the two soft boards and hard boards are produced, according to the planning requirements of the electronic engineer, the FPC and PCB are seamlessly pressed by the press. After a series of process production, the soft and hard bonding board is finally made. This is one of the most important aspects, because the hard and soft combination board is difficult and has many details. Before shipment, it is generally necessary to carry out full inspection, because of its high value, so as to avoid the loss of relevant interests between the supply and demand sides.

Contact Us Today

Contact Us Today