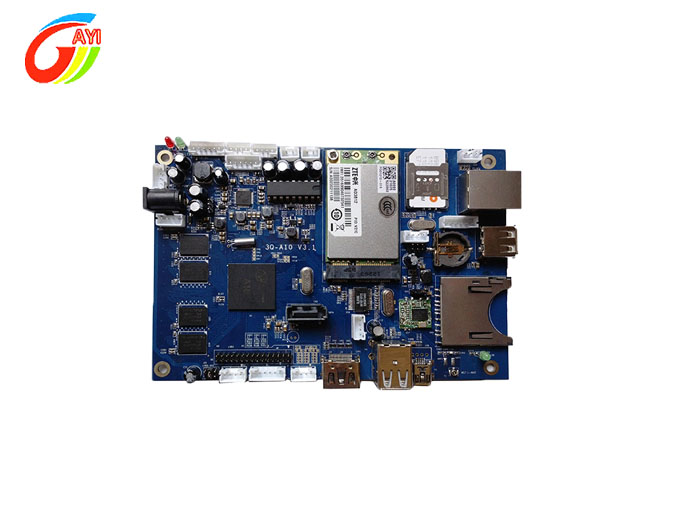

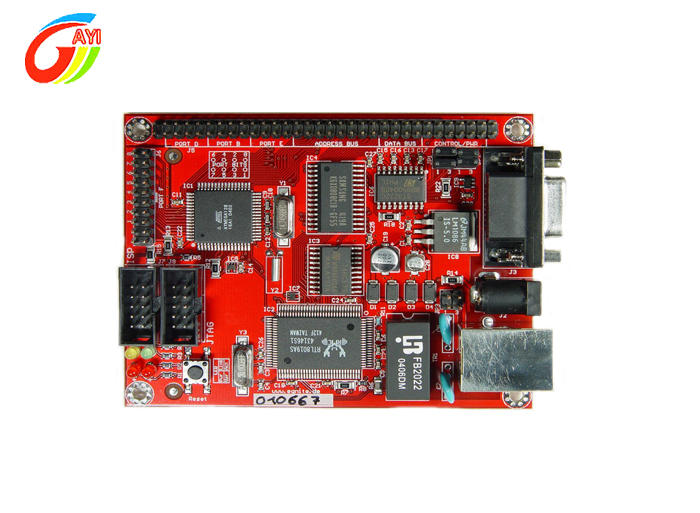

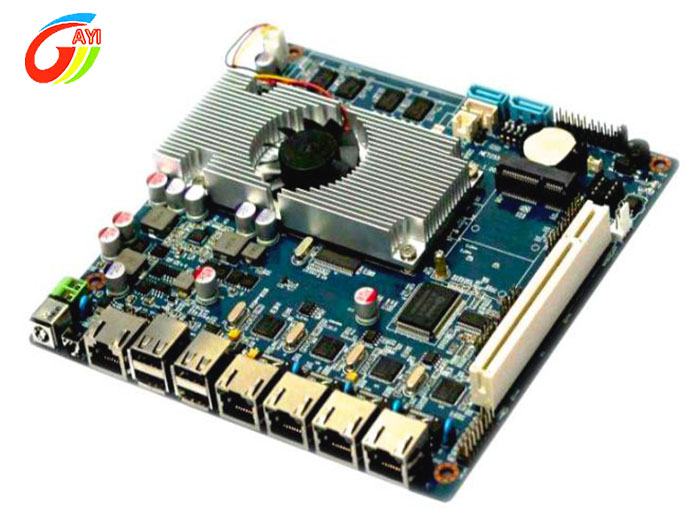

SMD board refers to the type of circuit board in which electronic components such as IC, diodes, resistors, etc. are directly pasted on the surface of the circuit board instead of being installed through holes. SMD boards have the advantages of being compact, space-saving, and easy to assemble, and are widely used in fields such as communications, computers, industrial control, and consumer electronics.

Features and advantages of SMD boards

1.Compact and space-saving: The design of SMD boards makes electronic components more compact and reduces the space occupied by circuit boards.

2.Convenient assembly: The assembly process of SMD boards is relatively simple, reducing the complexity of manual operations.

3.High-density integration: SMD boards can achieve high-density component layout and improve the integration of circuits.

Application areas of SMD boards

Due to their compactness, space-saving, and easy assembly characteristics, SMD boards are widely used in the following fields:

1.Communication equipment: such as mobile phones, routers, etc.

2.Computer hardware: such as motherboards, graphics cards, etc.

3.Industrial control equipment: such as automatic control systems.

4.Consumer electronics: such as TVs, stereos, etc.

Difference between SMD and Plugin

1.Installation method: SMD is to install components by surface pasting, while Plugin is to install through jacks.

2.Space utilization: SMD is more space-saving and suitable for high-density integrated design; Plugin requires more space to install components.

3.Assembly difficulty: The assembly of SMD is relatively simple and suitable for automated production; the assembly of Plugin requires more manual operation.

In summary, SMD plays an important role in the manufacture of electronic equipment with its compact, space-saving and easy assembly characteristics, especially in products that require high-density integration.

Contact Us Today

Contact Us Today