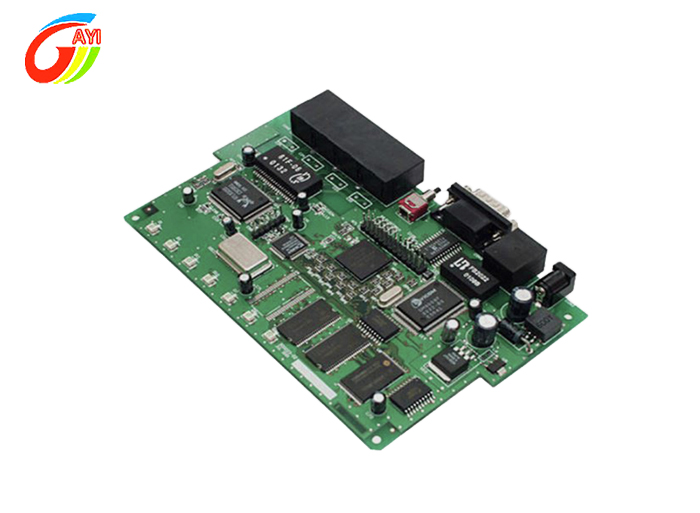

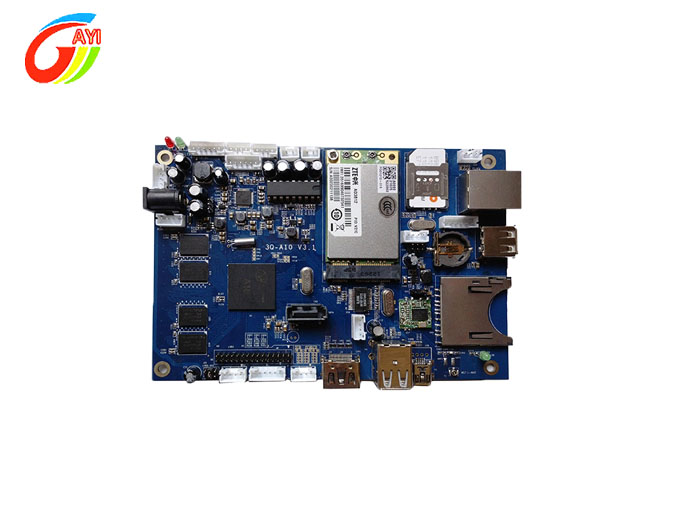

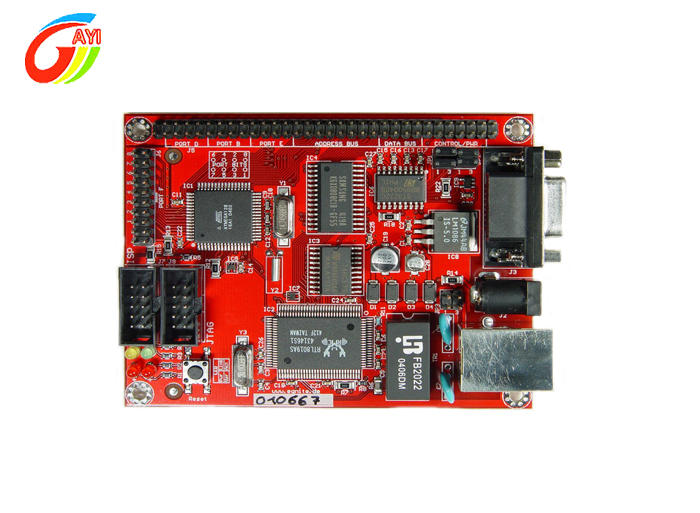

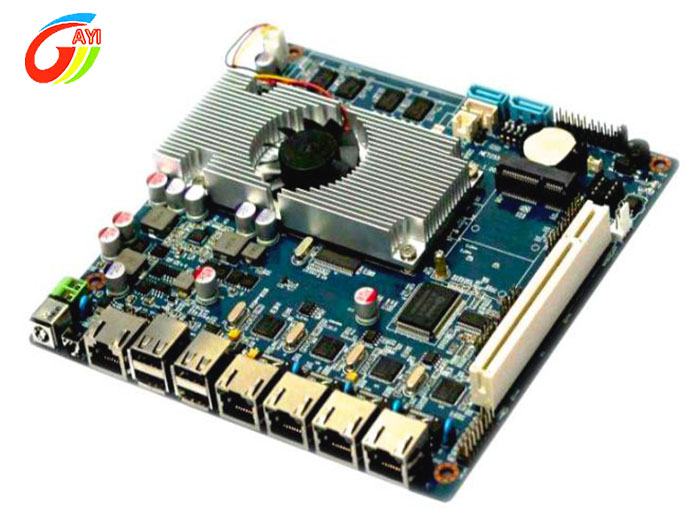

SMT patch technology is a technology that directly mounts pinless or short-lead surface mounted components (referred to as SMC/SMD)on the surface of a printed circuit board(PCB)or other substrate surface. This technology uses methods such as reflow soldering or dip soldering to solder and assemble components to the PCB board to form a complete circuit connection.

SMT patch technology process:

1.Material preparation: Prepare raw materials such as PCB boards,electronic components, and solder paste.

2.Silk screen printing: Use a silk screen printer to print solder paste on the pads of the PCB board to prepare for the soldering of components.

3.Mounting:Use a patch machine to accurately mount components on the pads of the PCB board.

4.Curing: Heat the solder paste to the melting point through equipment such as a hot air furnace to form a firm solder connection between the components and the PCB board.

5.Inspection: Use equipment such as AOI (automatic optical inspection)to perform quality inspection on the soldered PCB board to ensure that the welding quality meets the standards.

Contact Us Today

Contact Us Today