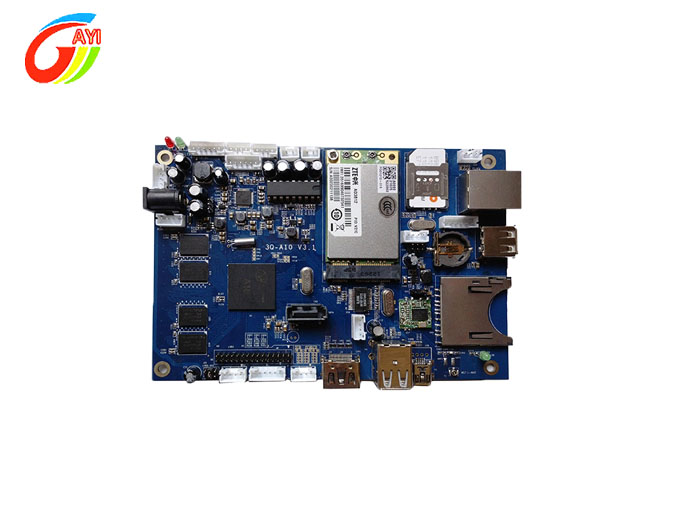

PCBA is the abbreviation of Printed Circuit Board Assembly in English, that is, the whole process of PCB empty board through SMT or DIP plug-in, referred to as PCBA.This is a commonly used writing method in China, and the standard writing method in Europe and the United States is PCB 'A, adding ', which is called official idiom.

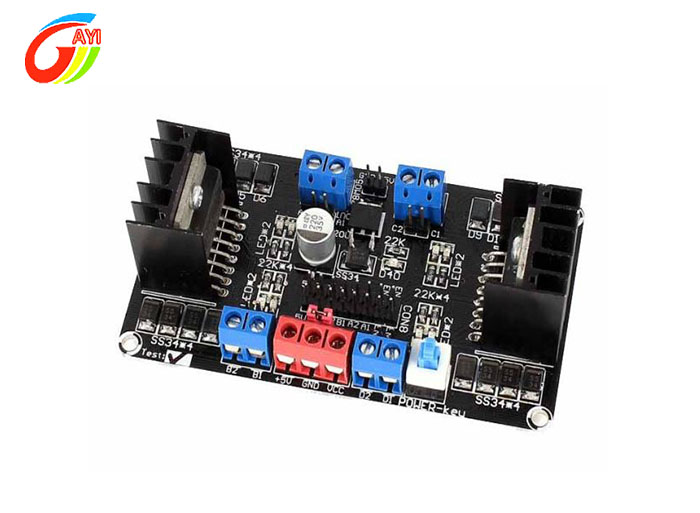

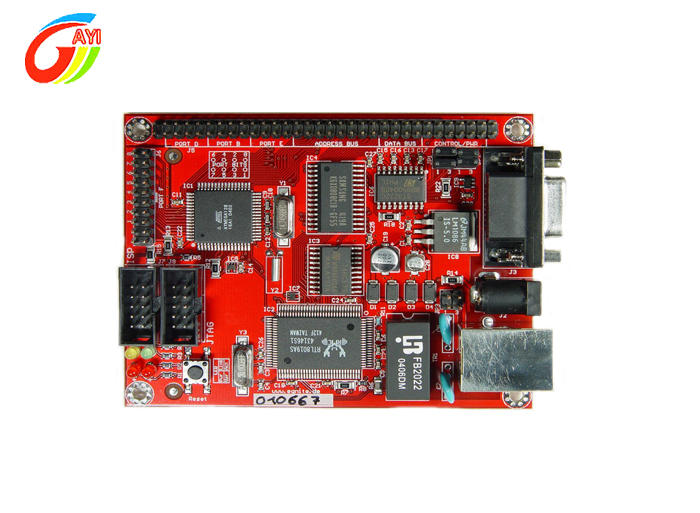

Both SMT and DIP are ways to integrate parts on the PCB board. The main difference is that SMT does not need to drill holes on the PCB, and DIP needs to insert the PIN foot of the part into the drilled holes.

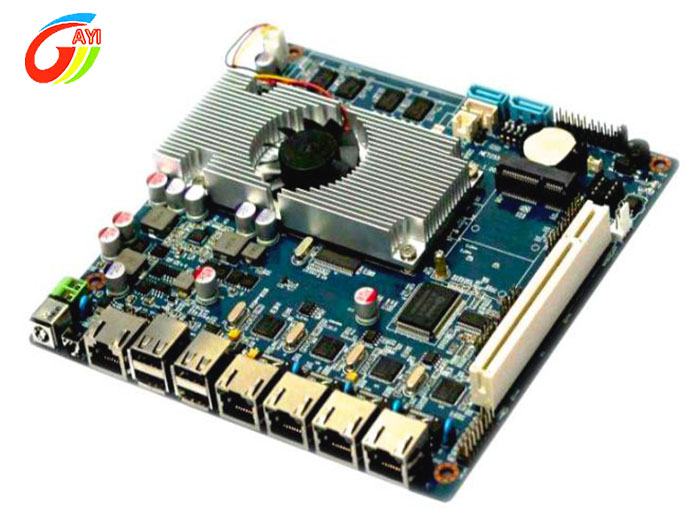

SMT (Surface Mounted Technology) surface mounting technology mainly uses the mounting machine to mount some small parts onto the PCB board. The production process is : PCB board positioning, printing solder paste, mounting machine mounting, back welding furnace and inspection. With the development of science and technology, SMT can also be used to mount some large-size parts, such as some large-size mechanism parts on the motherboard. SMT integration is very sensitive to positioning and part size. In addition, the quality of solder paste and printing quality also play a key role.

DIP is plug-in that is, inserting parts on the PCB version. Because the parts are large in size and are not suitable for mounting or when the manufacturer 's production process cannot use SMT technology, the parts are integrated in the form of plug-ins. There are two ways to realize manual plug-in and robot plug-in in the industry. The main production process is : backing glue (to prevent tin plating to undue places), plug-in, inspection, wave soldering, brushing (to remove stains left in the furnace process) and inspection.

Contact Us Today

Contact Us Today